Industry > Caneite

Caneite

CSR was always alert to opportunities, and had the skilled engineers and the capital to grasp them. As well as sugar and industrial spirits, the company added a third string to its bow.

The fibre that remains after sugar cane has been crushed – bagasse – can be used as fuel, but can also be processed into a usable material, and CSR sugar mills had much more bagasse than they could use for fuel.

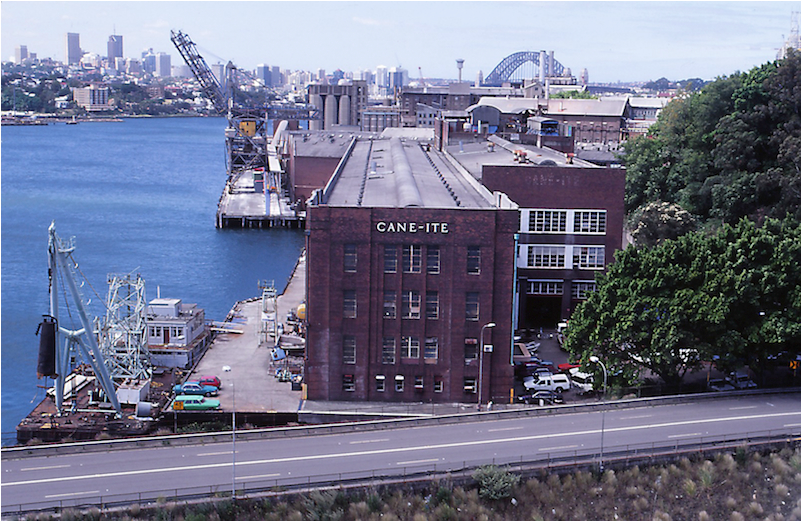

In the 1930s, as the Depression lifted, managers noticed a demand for building material. After exhaustive research, CSR built a factory on the northern shore of the peninsula, to mass-produce a wallboard called caneite, by pulping bagasse in defibrators, and adding water and binder. This was spread evenly and passed through rollers to achieve the correct density and thickness, cured with heat, cut and stacked.

By 1939 production reached ten million square feet each year. Encouraged by this result, CSR spread into other building materials including gyprock (and – fatefully – asbestos).